Specimen of Cost Sheet: It’s Meaning, Importance and Accounting Treatment!

Meaning and Definition:

The expenses of a product are analysed under different heads in the form of statement. This statement is called cost sheet.

Walter & Bigg define, Cost sheet as follows:

“The expenditure which has been incurred upon production for a period is extracted from the financial books and the stores records, and set out in a memorandum or a statement. If this statement is confined to the disclosure of the cost of the units produced during the period, it is termed as a cost sheet”.

ADVERTISEMENTS:

In other words cost sheet is a statement showing the total cost under proper classifications in a logical order.

Importance, Advantages, Objectives or Purpose of Cost Sheet:

Cost sheet is very important because it acts as the basis or foundation to ascertain costs and determine selling price of the output.

1. It provides details of total cost under logical classification.

2. It provides cost per unit in different stages.

ADVERTISEMENTS:

3. It helps in comparison and control of cost.

4. Cost sheet is helpful in estimation of cost for preparation of tenders and quotations.

5. It acts as basis for fixation of selling price.

Cost Sheet and Production Account:

Cost sheet is a statement of total cost under different classifications of cost. The classification of cost is done on the basis of elements of cost, functions and behaviour of cost. The total cost in the form of cost of sales and cost per unit is revealed.

ADVERTISEMENTS:

On the other hand, the cost, sales, and profits presented in the form of a ledger account is known as production account or manufacturing account. The debit side of the account is shown with opening stock, expenses and the credit side is shown with closing stock and sales. The balancing figure is either profit or loss.

Cost Sheet vs. Production Statement:

The cost of output can be ascertained from the statement known as cost sheet. The items of various costs are extracted from financial books and presented in logical order. Thus, total cost of a cost centre or cost unit is shown in the cost sheet.

When sales, stocks and profits are included in the cost sheet it is called production statement. Bigg has defined it as “The expenditure which has been incurred upon production for a period is extracted from the financial books and stores records and set out in a memorandum statement. If the statement is confined in the disclosure of the cost of the units produced during the period it is termed as cost sheet, but where the statement records, both cost, sales and profit it is usually known as production or output statement or account”. However the modern practice is to extend the cost sheet to show profit and sales also and call it “statement of cost and profit”.

Prime Cost:

ADVERTISEMENTS:

This is also called direct cost. It is the aggregate of direct materials, direct labour and direct expenses, which are easily identifiable with the product.

Works Cost:

It consists of the total of all items of expenses incurred in the manufacturing of a product, viz., prime cost plus factory expenses. It is also known as factory cost or manufacturing cost.

ADVERTISEMENTS:

Cost of Production:

This includes works cost and administration expenses. Production is not deemed to be complete without the managerial and facilitating costs.

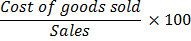

Cost of Sales:

It represents cost of production plus selling and distribution cost incurred. Thus, the cost of sales is the aggregate of all the direct and indirect costs connected to the goods sold.

ADVERTISEMENTS:

When profit is added to the cost of sales, sales can be found. Usually, selling prices are fixed on the basis of the cost of sales. It ensures that all the costs are recovered and any desired profit is also obtained.

Treatment of Stocks or Inventories:

Stocks of Raw Materials:

When opening stock of raw materials, purchase of raw materials and closing stock of raw materials are given, raw materials consumed can be calculated as follows:

1. Stocks of Work-In-Progress:

ADVERTISEMENTS:

‘Work-in-progress’ means units of production on which work has been done but are not yet completely finished. Work-in-progress is valued on prime cost or works cost basis but the latter is preferred.

The opening and closing work-in- progress are adjusted as given below:

2. Stock of Finished Goods:

If opening and closing stocks of finished goods are given they are to be adjusted to find out cost of production of goods sold.

3. Tenders and Quotations:

Frequently the manufacturers of consumer durables and capital goods are asked to quote the price at which they can supply their output. The price at which the items of output are offered for sale is known as ‘tender’ or ‘quotation’ price. The tender has to be prepared carefully since it may be accepted and goods have to be supplied in future at the quoted rate.

In order to prepare the tender the following items are to be analysed:

1. Raw materials

2. Direct labour

3. Chargeable expenses

4. Works overhead

5. Office overhead

6. Selling overhead, and

7. Estimated profit.

Estimation of different elements of cost has to be made.

The following are the accepted norms:

(A) Direct material and direct labour costs are generally estimated on the basis of ‘cost per unit’ of preceding period, subject to fluctuations in the market price of materials and labour rates.

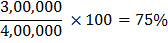

(B) Overhead is estimated on the basis of past experience as a percentage, as given below:

The above overhead percentages obtained on the basis of preceding period’s cost sheet are used for preparation of tender, after giving due regard to likely changes anticipated.

(C) Estimation of Profit for a Tender or Quotation: