Everything you need to learn about the Type of Incentive Plans as studied in Human Resource Management!

Types of Incentive Plans – Individual Incentive Plans and Group Incentive Plans

Incentive wage payment systems provide for additional payment of the better performance of workers over and above the ‘standard’ performance. The standard may be set on the basis of earlier experience regarding the job’s output, or it may be a result of time and motion studies, and also job evaluation studies.

This standard is based on an average worker’s capacity, without causing him undue strain. Individual output over and above this is then considered for the premium or bonus. Almost all incentive plans provide for minimum guaranteed wages on hourly basis. Some incentive plans use piece rates while others include time-saving and premium bonus plans. The plans are based on various formulae which are complex for the workers to understand without proper explanation.

There are two types of Incentive Plans:

ADVERTISEMENTS:

1. Individual Incentive Plans and

2. Group Incentive Plans.

1. Individual Incentive Plans:

Individual incentive plans may be either time-based or production-based. In time-based plans, worker is rewarded for better performance on the basis of time saved in completing a minimum standard of work in standard time. Halsey or Rowan plans are best examples of such plans. Standard time for an operation or for a certain quantum of production is fixed in the first instance.

If a worker can save on this time he is available for more work resulting in higher production. For instance, say, the standard time for a job is eight hours and the worker completes it in six hours, he has saved 25% time. Now supposing he was to get Rs. 16/- for eight hours, in fact he has earned that amount and still has saved two hours in which he can give production worth Rs. 4/-. This amount is certainly the result of his extra effort and he gets from 50-60% of this amount, the remaining going to the management.

ADVERTISEMENTS:

Under production based plans, a worker is allowed a standard work to be performed in standard time, and bonus is paid only if he completes the standard work within the given time otherwise no bonus will be paid to him.

Taylor’s and Gantt’s plans are best examples of this type. Incentive plans provide that for producing units of work beyond the standard expected of an average worker, an individual receives remuneration increments proportional to increases in output. The worker may be paid on a direct proportion basis or the worker and the company may share the amounts saved by worker’s increased output by varying proportions.

Some of the more widely known individual incentive plans are briefly as follows:

i. Simple Incentive Plan:

ADVERTISEMENTS:

The piece -work method is perhaps one of the oldest and simplest of the incentive plans. Calculations are based on rate per piece multiplied by the number of pieces produced. “Regardless of the approach to standard setting, the base hourly rate for the job is divided by the standard number of pieces per hour set for piece.”

Sometimes the base rate is set below the going hourly rate in order to induce the worker to produce above the standard.

ii. Halsey Premium Plan:

ADVERTISEMENTS:

This plan attempts to combine the merits of the time and piece rates and eliminate their limitations. Under this plan, certain quantity of work as a “standard output” is fixed on the basis of an average worker’s result of past efforts which is to be completed within a prescribed time. A worker who completes the work before that time, receives a reward according to the time saved in the form of a portion of wages in addition to his usual wages.

For instance, if the time prescribed for a standard work output is 10 hours and this quantity of work is completed in 8 hours, the individual under this plan would receive in addition to hours at time rate, a portion (say 50%) of the two hours saved. Suppose the time-rate is Rs. 1 per hour, the premium bonus under this plan would be-

The worker is guaranteed a time wage and is given a bonus at fixed rates for every hour saved.

ADVERTISEMENTS:

iii. Rowan Premium Plan:

This plan differs from Halsey Plan only in regard to the determination of bonus. In every other respect, both are the same. The worker is guaranteed a minimum wage on the time basis and then a “standard time” is fixed for the completion of every work and if the worker completes the work in less time, he is given a premium bonus of the time actually saved in proportion to the total time.

The premium bonus under this plan would be thus equal to:

Time Saved divided by Standard Time multiplied by (Time Taken x Rate)

ADVERTISEMENTS:

Suppose the “Time Rate” is 1 per hour, the “Standard Time” is 10 hours, “Time Taken” to complete the work is 8 hours and thus “Time saved” is 2 hours, the premium bonus under this plan would be

(2 + 10) x (8×1) = (2x8x1)/10 = Rs.1.60

Thus the bonus would receive in all

Rs. 8×1 = Rs. 8 + Rs.1.60 = Rs. 9.60

ADVERTISEMENTS:

The plan aims at ensuring the performance of the premium rate, which is often cut by the employer when the worker’s efficiency increases beyond a certain limit. It is advocated that the low rates of premium bonus under the Halsey and Rowan Plans provide a really effective guarantee against any rate-cutting by employer and, therefore, the adjustment of remuneration to output on the whole is closer under these systems than it would be under price wages.

iv. Taylor’s Differential Piece Rate Plan:

Under this plan, a “standard of output” is first fixed or determined per hour or per day using time and motion study and then two piece wage rates are prescribed – a relatively high piece rate is applied above the fixed standard and the rate below the standard is very low. In other words, workers who attain or exceed the standard are paid at the higher rate and those whose output is less, receive the lower rate.

Since the system does not prescribe any basic guaranteed time wage, it aims of encouraging the best class of workers as against inducing workers of a lower calibre to improve themselves or quit, if they consistently fail to make standard. Thus this system penalizes the slow worker and rewards workers giving high output.

v. The Gantt Task and Bonus Plan:

This is a modified variety of Taylor Plan which guarantees to the worker the payment of ordinary time wages for all output below the standard established by time and motion study. The worker, whose performance is above the standard, is paid a large premium bonus – a bonus percentage multiplied by the value of standard time.

ADVERTISEMENTS:

Under this system, fixed time-rates are guaranteed. Output standard and time standards are prescribed for the performance of each job. Workers completing the job within the standard time or in less time receive wages for the standard time plus a bonus which ranges from 20% to 50% of the time allowed and not time saved. When a worker fails to turn out the required^ quantity of a product, he simply gets his time rate without any bonus.

Thus, there are three stages of payment:

(i) Below the standard performance – only the minimum guaranteed wage is to be paid.

(ii) At the standard performance – this wage plus 20% of time rate will be paid as a bonus.

(iii) When the standard is exceeded – a higher piece-rate is paid but there is no bonus.

This system is most profitable for workers whose efficiency is very high. The basic wages rise proportionately as under ordinary piece wage system, and the bonus is allowed on the increased wage. In addition to this, workers with low efficiency are not penalized, as they are in Taylor’s Differential Piece Rate.

vi. Emersion Efficiency Plan:

Under this system, the worker’s daily wage is guaranteed. A standard time is established for a standard task. There is no sudden rise in wages on achieving the standard of performance. The remuneration based on efficiency rises, gradually. Efficiency is determined by the ratio between standard time fixed for performance and the actual time taken by the worker.

Thus, if the standard time is 8 hours and the actual time is 16 hours, his efficiency is 50%. He who finishes the task in 8 hours has 100% efficiency. No bonus is paid to a worker unless he attains 67% efficiency, at which stage he receives a nominal bonus. This bonus goes on increasing till, when he achieves 100% efficiency, the bonus comes to 20% of the guaranteed wage. At 120% efficiency, worker receives a bonus of 40% and at 140 efficiency the bonus is 60% of day wage.

2. Group Incentive Plans:

As against individual incentive plans, there are group incentive plans which induce the whole group of workers. Under this system, each member of the group is rewarded on the basis of performance of his group. This system is very useful where output of individual workers cannot be measured although output as a group of workers can be easily measured. The accent in group plans is primarily upon cooperation toward a mutual objective.

The focus in the group incentive plan is on the group achieving a certain standard of output and thus qualifying for the incentive wage. A team approach is called for, with all the members doing their share to achieve and maintain the output. Such group efforts can be offered group incentives on the basis of the piece work or its variation, as well as the standard hour plan. Some group incentive plans are plant-wide systems from which Scanlon Plan is the most well-known one.

Scanlon Plan:

This plan operates at the plant level as a means of achieving union management cooperation towards the goal of increased productivity. The incentive feature of the plan is a bonus that is paid monthly to gain the benefits of prompt reward and which is calculated from savings in labour cost.

This approach requires the compensation of a normal labour cost per unit of product produced. If through more cooperation and greater efficiency labour costs can be reduced, the entire amount saved, or some fraction, is distributed among the workers in the form of a bonus. For example- it may be determined from past records that labour costs constitute 30% of sales.

If through cooperative efforts these costs can be reduced to 28%, then 2% of sales is divided among employees on the basis of seniority and/or salary levels. Usually 80% goes into direct bonus and 20% is kept by management for covering deficit periods. Scanlon claimed that individual incentive plans stimulated cut-throat competition to the detriment of the group, whereas group incentives effected constructive cooperation.

Essential features of the plan are an attitude of labour-management cooperation and a system of processing suggestions for increased efficiency which are evaluated by a complex committee structure giving the union and management equal representation.

The plan thus emphasizes participative management and joint planning between the company and the union. Scanlon plan has been adopted with varying degrees of sources in several U.S. organizations; however there are also instances where it has been tried and failed. “It is a difficult plan to put into effect and to maintain because it involves complex changes in the social structure and organization plant and union relationships”.

There are certain difficulties and problems in the operation of wage incentive plans. In many cases incentive schemes have been abandoned mainly due to the frequent disputes which cause considerable damage to the industrial relations climate at the plant level. There are many instances in which full motivation potential of the incentive is not obtained largely as a result of a quite conscious restriction of output by workers themselves.

Group output restriction is not the only problem, there are several other difficulties like the reaction to changes in methods, equipment, and materials; difficulty to set truly appropriate standards. Moreover, deterioration in the quality of the product in order to maintain high output is yet another problem. The setting of timings and base rates is a continuous source of friction, and re-adjustments are difficult to implement.

There is also a danger that safety regulations would be disregarded by workers and this may result in higher accidents. Workers may tend to over work and undermine their health. Several times, differences in earnings could cause jealousies and misunderstandings among the workers. Many schemes work against those who are willing or disabled or advanced in age. Workers develop a tendency to regard their highest earnings as their expected normal wage and consequently try to push up the base rate.

Most of these problems revolve around employee fear of management and a desire for security.

Types of Incentive Schemes – Individual and Group Incentive Systems

An organization may use a variety of incentive schemes. It can be designed to reward the performance of the individual, group, business plant, entire organization or any combination of these.

The main incentive schemes are the following:

1. Individual Incentive Systems:

These are the most widely used incentive systems in industry. Here, an organization attempts to identify and reward the contribution of individual employees.

I. Straight Piece Work System:

This is the oldest and simplest method. It is also most commonly used method. In this method, the rate per unit of output is fixed and the total wages of a worker are arrived at by multiplying the total output by the rate per unit. The total output is measured in terms of unit. For example, if the rate per unit is Rs. 1 and the total output of an employee is 50 units, then his wages will be 50 × 1 = Rs. 50. However, employee’s time-rate is guaranteed here.

II. Standard Hour System:

In this system, standard time in terms of hours is fixed for the job completion. Rate per hour is determined. An employee is paid according to standard time wages. If the employee takes more than the standard time then he or she will be paid the same wages unless it is guaranteed time wages. If time wages are guaranteed, the employee is paid on the basis of time taken multiplied by the time-rate.

For example:

Standard time = 8 hours

Rate per hour = Rs. 1

1st Case –

Time Taken = 6 hours

Wages = 8 × 1= Rs. 8

2nd Case –

Time taken = 10 hour

Wages if time wages are not guaranteed = 8 × 1= Rs. 8.

Wages if time wages are guaranteed = 10 × 1 = Rs. 10.

III. Time-Based Systems:

(i) Halsey Plan:

This plan was developed by F.A. Halsey. Under Halsey plan, a standard time is fixed in advance for completing the job. An employee taking standard or more time is paid for the time taken by him. An employee completing his or her job in less than the standard time is paid for some of the time saved.

In other words, if the worker completes the job in less than the standard time, he will receive a bonus payment at his time rate for a specific percentage of the time saved. This percentage may vary anywhere from 30 per cent to70 per cent, but usually it is fixed at 50 per cent (the rest 50 per cent goes to the employer).

Wages = (T × R) + [(S – T)/2] × R

Where S = Standard time

T = Time taken

R = Hourly rate

For example:

Standard time =12 hours

Rate per hour = Rs. 1

1st Case –

Time taken = 12 hours

Wages = 12 × 1 = Rs. 12

2nd Case –

Time taken =13 hours

Wages = 13 × 1 = Rs. 13

3rd Case –

Time taken = 10 hours

Wages = (10 x 1) + [(12 – 10)/2] × 1 = Rs. 11

Merits:

(a) Halsey plan guarantees minimum wage to all workers, which creates a sense of security.

(b) The wages of time saved are divided between the employer and employee. Thus, this plan benefits the employer also.

(c) This plan is simple to introduce and easily understood by the workers. They can easily make their calculations.

(d) Workers can utilize their saved time in doing other jobs and earn more.

Demerits:

(a) Difficulty arises in fixing standard time for completing a job.

(b) Quality of goods may suffer as workers may try to finish the work in the shortest possible time.

(c) More supervision is required to ensure that workers in their eagerness to complete the work fast do not waste materials unduly or damage the machines and tools.

(d) Workers do not receive full benefits for their efforts as usually they are paid for half of the time saved, the other half goes to the employer.

(ii) Halsey-Weir Plan:

This plan was developed by Messer’s G & J Weir Ltd. of Glasgow in 1900. This plan is just another form of Halsey plan. Under this plan, a worker receives 30 per cent of the time saved (i.e. standard time-actual time taken). Similar to Halsey plan, a minimum wage is guaranteed here also.

(iii) Rowan Plan:

This plan was developed by James Rowan in 1898. In this plan also, a standard time and rate per hour are fixed. This plan differs from Halsey plan only in respect of the determination of the bonus. The bonus is calculated on the basis of the proportion which the time saved bears to the standard time.

Bonus = (Time saved/standard time) × Time taken × Hourly rate

For example:

Standard time = 12 hours

Rate per hour = Rs. 1

1st Case –

Time taken = 12 hours

Wages = 12 × 1 = Rs. 12.00

2nd Case –

Time taken = 13 hours

Wages = 13 × 1 =Rs. 13.00

3rd Case –

Time taken = 10 hours

Wages =10 × 1 = Rs. 10.00

Bonus = (2/12) × 10 × 1 = 1.66

Total wages = 11.66

Merits:

(a) It guarantees minimum wages to workers.

(b) Increase in production reduces overhead cost per unit.

(c) It enables the employer of the share in the benefits of increased output.

Demerits:

(a) This plan is more complex and expensive than the Halsey plan.

(b) This plan’s incentive value is low at high production levels, thus this is unjust to efficient workers.

(iv) Bedeaux Plan:

This plan was developed by Charles E. Bedeaux in 1911. In this plan, each minute of the allowed time is called a Bedeaux point or ‘B’ in short. There are 60 B’s in one hour. Each job has a standard number of B’s and the hourly rate is also determined. In addition to hourly rate, a worker receives a bonus calculated at 75 per cent of the points earned in excess of 60 per hour, multiplied by one-sixtieth of the worker’s hourly rate.

For example:

Standard time = 12 hours

Rate per hour = Rs. 1

Time taken =10 hours

Standard B’s = 60 × 12 = 720 B’s

Actual B’s = 60 × 10 = 600 B’s

Saving in terms of B’s = 120 B’s

Wages = 10 × 1 = Rs. 10.00

Bonus = (75/100) × [(120 × 1)/60] = Rs. 1.50

Total wages = 10 + 1.50 = Rs. 11.50.

(v) Differential Piece Rate Plans:

Under these plans different piece rates are set for different amounts of outputs which may be recognized either by actual numbers or pieces or as percentage of tasks.

The important ones are the following:

(a) Taylor’s Differential Piece-Rate System:

This system was developed by F.W. Taylor in 1880. Under this plan, there are two piece rates, namely high rate and low rate for each job or task. For each job, standard output and task time are established. If the output of workers is equal to or exceeds the standard, he or she receives wages at the higher rate to enable them to get the bonus.

On the other hand, if the output of the worker is less than the standard, then he or she receives wages at the lower rate. Then standard is determined on the basis of time and motion studies. This plan is basically designed to encourage the especially efficient worker with a higher rate of payment and to penalise the inefficient worker by a lower rate of payment. However, this plan is rarely used now.

Illustration:

Standard output = 10 units

Rate – (i) High rate = Rs. 5 per unit

(ii) Low rate = Rs. 2 per unit

Case (i) actual output = 10 units

In case actual output equal or exceeds standard output,

Wages = 10 × 5 = Rs. 50

Case (ii) in case actual output is below the standard output (actual output = 8 units)

Wages = 8 × 2 = Rs. 16

(b) Merrick Differential Piece-Rate System:

This system was developed by D.V. Merrick. This system is the modification of Taylor’s system. Merrick realized that it was unreasonable and unrealistic to classify all the employees into two broad categories only, i.e., workers of high efficiency and workers of lower efficiency because there are various degrees of efficiency and there are many workers who actually put their efforts to produce more.

These kind of persons need to be encouraged. This system introduces three piece rates and made the lowest piece rate equal to the ordinary rate which becomes the base piece rates.

The rates introduced by Merrick are the following:

Output (Percentage of Task) – Piece Rate Wage:

Less than 83% – Basic piece rate

From 83 % to 100% – 110% of basic piece rate

Over 100% – 120% of basic piece rate

For the potentially high producer, this plan is a good incentive system. This plan pays a production bonus at 10 per cent of the basic rate to the workers when they reach 83 per cent task and further 10 per cent bonus on reaching over 100 per cent.

(c) Gantt’s Task and Bonus Plan:

This system was developed by H.L. Gantt, a close associate of F.W. Taylor, in 1901. Gantt is considered as one of the pioneers of scientific management. He modified Taylor’s plan considerably. The significant modification is the substitution of Taylor’s punitive wage rate by a guaranteed basic wage.

Under this plan, a worker’s wage consists of two parts, which are the following:

(I) A guaranteed minimum wage on time rate, which is usually an hourly rate.

(II) A bonus, which is paid to the worker when output is equal to or more than the task. The bonus is a percentage of the guaranteed wage. Bonus varies from 20 per cent to 50 per cent of the guaranteed wage.

(d) Emerson Efficiency Plan:

This plan was developed by Harrington Emerson in 1919. Under this plan, whenever the efficiency of a worker reaches 67 per cent, he will get a bonus. Then as the efficiency increases the bonus also increases. When a worker’s efficiency varies from 67 per cent to 99 per cent, he receives a bonus at different percentages of his basic wages. And when the efficiency is 100 per cent, the worker’s bonus is 20 per cent of the basic wage.

Further, when the efficiency is more than 100 per cent, for every 1 per cent increase in efficiency there is a 1 per cent increase in bonus. Just like other incentive plans, a minimum wage is also guaranteed in this plan. The efficiency of a worker should be determined on the basis of the monthly or at least worker’s weekly output.

Merits:

(I) This plan is simple and easily understood by workers.

(II) Minimum wages are guaranteed.

(III) In this plan, whenever the efficiency of a worker reaches 67 per cent he or she will get bonus. In addition, the rate of bonus increases progressively. Thus, it provides a stimulus to employees for increasing their efficiency.

Demerits:

(I) Wage calculations require careful attention.

(II) Employees may not be encouraged to increase their output beyond the standard level, as rewards may be nominal.

(e) Accelerated Premium Plans:

Under this system, the earnings of the employees increase with output, the rate of increase itself rising progressively with the output. The employees receive a strong reward or incentive to increase their output in order to obtain increased earnings. However, this is a complicated system and not easy to understand and administer.

2. Group Incentive Systems:

Many incentive plans are for individual workers. However, in many cases the output of individual workers cannot be measured although output as a group of workers can be conveniently measured. In such situations group incentive systems are very useful. Under situations where workers are engaged in the assembly work, for example automobiles, textiles, grinding and welding, etc., group incentive schemes are followed.

Advantages of group incentive plans:

(i) It creates cooperation and team spirit among workers.

(ii) There is less need of inspection and supervision.

(iii) The calculation of wages requires less clerical work.

(iv) It raises production and reduces wastage.

(v) It reduces absenteeism.

(vi) It guarantees time wages and thus it creates a sense of security in the workers’ mind.

Disadvantages of group incentive plans:

(i) It does not distinguish between efficient and inefficient workers in a group for the purpose of proper distribution of bonus.

(ii) The incentive may be insignificant to motivate the workers.

(iii) Difficulty arises in the determination of the basis of distribution of bonus.

(iv) Jealousy and rivalry among workers defeats the very purpose of teamwork and cooperation.

Types of Group Incentive Plan:

I. Profit-Sharing Plan:

Employee profit-sharing plans constitute one of the more glamorous forms of monetary compensation used in business. In 1897, the International Cooperative Congress defined employee profit sharing as an agreement freely entered into, by which the employees receive a share, fixed in advance of the profits. The employee profit-sharing plans are mainly of two types.

These are- (i) cash or current distribution and (ii) trust or deferred distribution. In the cash or current arrangement, the benefits are distributed among participants in cash at least once each year. The deferred type involves a trust fund, the benefits from which are distributed in the event of death, retirement or disability. Some managers prefer to place a part the profit share in trust and distribute the remaining part in the form of cash each year.

The main features of profit-sharing are the following:

The profit-sharing arrangement is voluntary but based on an agreement between the employer and the employee.

In it, there is following arrangement:

(i) The amount to be distributed amongst the participants depend upon the profits earned by the enterprise, and

(ii) The proportion of the profits to be distributed is determined well in advance.

(i) To secure employee cooperation and to maintain industrial harmony.

(ii) To promote employee loyalty towards organization by supplementing his or her earning.

(iii) To promote increased employee effort.

(iv) To strengthen unity of interest between the employer and the employees.

Advantages of Profit-Sharing:

(i) It effects an increase in productive efficiency through reducing costs and increasing output.

(ii) This scheme is relatively easy and less expensive to adopt.

(iii) It improves employee morale.

(iv) It results in cordial relations between the employees and the employer.

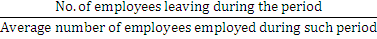

(v) It reduces labour turnover.

(vi) It provides security for the employee in the event of disability, death and retirement.

(vii) It provides additional earning to the employees.

(viii) It constitutes a mechanism for employees, economic education.

(ix) It enhances team spirit among employees.

Disadvantages of Profit-Sharing:

(i) This scheme does not distinguish among individuals on the basis of effort and contribution. In other words, it does not differentiate between efficient and inefficient workers.

(ii) Besides labour there are many other factors that affect profits. For example, economic and social factors, government policies, demand of the product, etc.

(iii) The employer may indulge in the manipulation of accounts.

(iv) Under this scheme, the extra compensation is not paid immediately after the employee effort is made.

(v) The main disadvantage of this scheme is its high discontinuance rate. These discontinuances are caused by such factors as employee apathy to profit-sharing appraisal, lack of profits, insufficient share, union opposition and unintelligent plan administration.

II. Employee Stock Ownership Plans (ESOPs):

ESOPs reward employees with company stock; either as an outright grant or at a favourable price that may be below market value. These plans are more common among major insurance companies, commercial banks, gas and electric companies and those with over half billion dollars in sales.

The main objective of ESOPs is to promote a mutuality of interests. Other possible values are the promotion of thrift and security, the creation of an added incentive to work productively and cooperatively and the creation of an additional source of investment capital.

Some salient features of ESOPs are as follows:

(i) Generally, a mechanism is adopted through which certain eligible employees may purchase the stock of the company at a reduced rate.

(ii) Usually, the eligibility is determined by the salary level or years of continuous service or both.

(iii) There is a provision for instalment buying. The employee authorises a payroll deduction, and stock is periodically purchased for him in the market by the company.

(iv) Sometimes, there is also a provision of the right to purchase a certain amount of stock in future at a stated price.

(v) ESOPs are most widely used in executive compensation plans rather than with the rank and file workers

Types of Incentive Plans – Top 11 Types of Chief Incentive Plans

The chief incentive plans are:

1. Halsey Premium Plan.

2. Halsey Weir Premium Plan.

3. Rowan Premium Plan.

4. The 100 per cent Premium Plan.

5. The Bordeaux Point Plan.

6. Taylor’s Differential Piece Rate Plan.

7. Merrick’s Multiple Piece Rate Plan.

8. Gantt Task Plan.

9. Emerson Efficiency Plan.

10. Co-partnership System.

11. Accelerating Premium Systems.

Type # 1. Halsey Premium Plan:

This is a time-saving bonus plan which is ordinarily used when accurate performance standards have not been established. Under this plan, it is optional for a workman to work on the premium plan or not. His day’s wage is assured to him whether he earns a premium or not, provided that he is not so incompetent as to be useless. A standard output within a standard time is fixed on the basis of previous experience.

The bonus is based on the amount of time saved by the worker. He is entitled to a bonus calculating on the basis of 331/3 per cent of the time saved. He thus gets wages on the time rate basis. If he does not complete the standard output within the stipulated time, he is paid on the basis of a time wage. The plan is a combination of the day wage and the piece wage in a modified form.

Example:

Suppose the standard time is 20 hours, the number of units to be completed is 10, and the hourly rate is 25 paise.

Then, the working of the scheme will be:

Example:

If 8 hours is the standard time of a job and Re. 0.50 is the guaranteed wage per hour, the worker, if he takes 8 hours to perform the work, receives Rs 4.00. If the person completes the task in less than 8 hours, he receives an extra premium on the time saved (i.e., for 2 hours).

Merits:

The merit of this plan are:

(a) It guarantees a fixed time wage to slow workers and at the same time, offers extra pay to efficient workers.

(b) The cost of labour is reduced because of the percentage premium system; the piece rate of pay gradually decreases with increased production.

(c) The plan is simple in design and easy to introduce.

(d) As the wages are guaranteed, it does not create any heartburning among such workers as are unable to reach the standard.

Demerits:

The disadvantages of the plan are:

(a) It depends upon past performance instead of making new standards.

(b) The workers can beat the game by spurting on certain jobs to capture a premium and soldiering on other jobs to rest under the protection of the guarantee of day wages.

(c) From the point of view of the administration, the policy is one of drift, for in this plan, the worker is left alone to decide whether or not to produce more after the standard has been reached.

Type # 2. Halsey-Weir Premium Plan:

This plan is similar to the Halsey Premium Plan except that 50 per cent of the time saved is given as premium to the worker.

Bonus = ½ x Time Saved x Hourly Rate

Type # 3. Rowan Premium Plan:

This plan differs from the Halsey Plan only in regard to the determination of the bonus. In all other respects, the two are the same. In the Rowan Plan, the time saved is expressed as a percentage of the time allowed and the hourly rate of pay is increased by that percentage so that total earnings of the worker are the total number of hours multiplied by the increased hourly wages.

The plan aims at ensuring the permanence of the premium rate, which is often cut by the employer when the worker’s efficiency increases beyond a certain limit. The premium is calculated on the basis of the proportion which the time saved -bears to standard time.

Example:

If 8 hours are the standard time for doing a job and Rs 4.00 per day wage, the premium and total wages would be as follows:

The Rowan Plan has all the merits and demerits of the Halsey Plan except that because of the limitation on earnings, it does not provide an incentive for maximum productivity. Moreover, the complex method of premium calculation is generally unintelligible to the worker. He cannot, therefore, be expected to take much interest in the plan.

These premium plans may be classified as differential piece work systems and have been evolved with a view to giving the benefit to both parties. They are based on the fundamental principle that a worker’s earning should increase when his production rises above a pre-determined target. As his extra earning is not in proportion to his usual wage rate, the overall production cost per piece falls when the output increases.

It will be seen that, for a little time saving, the Rowan Plan gives more bonus than the Halsey or the Halsey-Weir Plans. Up to 50 per cent of the time saved, the bonus earned under the Halsey-Weir or the Rowan Plan is equal; but above 50 per cent of the time saved, the Rowan Plan pays more than the Halsey Plan.

However, under the Rowan Plan, a worker gets his maximum bonus when he completes the task in half the standard time allowed. If he saves more than 50 per cent of the time, the bonus he earns decreases, and his increase in wage is at a diminishing rate. But under the Halsey and Halsey-Weir Plan, it is progressively higher.

Hs = the hour allowed or standard time.

Ha = the actual time taken on a job.

Rh = the work rate per hour.

Type # 4. The 100 Per Cent Premium Plan:

Under this plan, task standards are set by time study or work sampling, and rates are expressed in time rates rather than in money (e.g., 0.20 hour per piece). A definite hourly rate is paid for each task-hour of work performed. The plan is identical with the straight piece-rate plan except for its higher guaranteed hourly rate and the use of task time as a unit of payment instead of a price per piece.

The worker is paid the full value of the time saved. If he completes the tasks of 10 hours in 8 hours and if the hourly rate is Rs 0.50, his total earnings will be Rs 8 x 0.50 + (10 – 8) x 0. 50 = Rs 4.00 + 100 = Rs 5.00.

Type # 5. The Bedeaux Point Plan:

This plan is used when careful assessed performance standards have been established. It differs from the 100 per cent plan in that the basic unit of the time is the minute termed as B. Every job is expressed in terms of Bs (after Bedeaux), which means that a job should be completed in so many minutes. If a particular work is rated at 60 Bs (or one B hour), the worker is allowed one hour for its completion and receives a bonus of 75 per cent for the number of Bs, i.e., time saved.

Suppose a worker earns 600 Bs in a day; if the rate per point is Rs 0.01, his total earnings would be:

Rs 4.80 x 0.01 + 3/4 (600 – 480) x .01.

= Rs 480 + Re. 0.90 = Rs 5.70.

The chief advantage of this plan is that it can be applied to any kind of a job. It is particularly suitable for plants in which workers are assigned diverse kinds of jobs, shifted from one job or department to another. All the points which a worker earns in a day are recorded and the bonus is calculated on that basis.

Type # 6. Taylor’s Differential Piece-Rate Plan:

This system was introduced by Taylor with two objects: first, to give sufficient incentive to workmen to induce them to produce upto their full capacity; and second, to remove the fear of wage cut. There is one rate for those who reach the standard; they are given a higher rate to enable them to get the bonus. The other is the lower rate for those who are below the standard, so that the hope of receiving a higher rate (that is, a bonus) may serve as an incentive to come up to the standard.

Workers are expected to do certain units of work within a certain period of time. This standard is determined on the basis of time and motion studies. Such scientific determination ensures that the standard fixed is not unduly high and is within the easy reach of workers. On a proper determination of the standard depends the success of the scheme?

This system is designed to encourage the specially efficient worker with a higher rate of payment and to penalise the inefficient by a lower rate of payment. In practice, this plan is seldom used now.

Example:

Let the standard time for the completion of 10 pieces of a job be 8 hours and the piece rate be Re. 1.00. Then the basic hourly rate comes to 12.5 paise. The one who completes the work within the allotted time is paid wages at a rate which is 320 per cent higher than the basic one.

It is evident that workers A, B and C are better off, and for them, the system is good; but for D and E, who are more than 100 per cent efficient, the effective price rate remains the same when compared with that of A, who is just 100 per cent efficient.

Type # 7. Merrie’s Multiple Piece Rate System:

This system too is based on the principle of a low piece rate for a slow worker and a higher piece rate for higher production; but the plan differs from Taylor’s Plan, in that it offers three graded piece rates instead of two- (i) Upto, say 83% of standard output a piece-rate + 10% of time rate as bonus; (ii) Above 83% and up to 100% of standard output — same piece rate + 20% of time rate and (iii) Above 100% of standard output — same piece rate but no bonus.

Such a scheme is usually introduced in an organisation where the performance level is already high and management is aiming at 100% efficiency. Management has some discretion in distributing the 20% of time rate over 17% of production above 83%.

Type # 8. The Gantt Task and Bonus Plan:

This plan has been devised by H.L. Gantt and is the only one that pays a bonus percentage multiplied by the value of standard time. Under this system, fixed time rates are guaranteed. Output standards and time standards are established for the performance of each job.

Workers completing the job within the standard time or in less time receive wages for the standard time plus a bonus which ranges from 20 per cent to 50 per cent of the time allowed and not time saved. When a worker fails to turn out the required quantity of a product, he simply gets his time rate without any bonus.

Under this plan, there are also three stages of payment- (i) below the standard performance, only the minimum guaranteed wage is to be paid; (ii) at the standard performance, this wage + 20% of time-rate will be paid as a bonus and (iii) when the standard is exceeded, a higher piece rate is paid but there is no bonus.

Example:

If the standard task for a day is 8 units and the day wage is Rs 4, the bonus at 50 per cent, the total wages would be.

This system is most profitable for workers whose efficiency is very high. The basic wages rise proportionately as under ordinary piece wage system, and the bonus is allowed on the increased wage. In addition to this, workers with lower efficiency are not penalised as they are in Taylor’s Differential Piece Rate.

Type # 9. Emerson Efficiency Plan:

Under this system, a standard time is established for a standard task. The day wage is assured. There is no sudden rise in wages on achieving the standard of performance. The remuneration based on efficiency rises gradually. Efficiency is determined by the ratio between the standard time fixed for a performance and the time actually taken by a worker.

Thus, if the period of 8 hours is the standard time for a task and if a worker performs it in 16 hours, his efficiency is 50 per cent. He who finishes the task in 8 hours has 100 per cent efficiency. No bonus is paid to a worker unless he attains 662/3 per cent efficiency, at which stage he receives a nominal bonus.

This bonus goes on increasing till the time he achieves 100 per cent efficiency, the bonus comes to 20 per cent of the guaranteed wage. At 120 per cent efficiency, a worker receives a bonus of 40 per cent and at 140 per cent efficiency the bonus is 60 per cent of the day wage.

Type # 10. Co-Partnership System:

This system tries to eliminate friction between capital and labour. Under this system, not only does a worker share in the profits of the undertaking but he also takes part in its control and, therefore, shares responsibilities.

There are different degrees of this partnership and control allowed to the operatives in different cases; but in a complete co-partnership system, the following factors are present:

(a) The payment of the existing standard wages of labour;

(b) The payment of a fixed rate of interest on capital;

(c) The division of the surplus profit between capital and labour in an agreed proportion;

(d) The payment for a part of the worker’s labour by the allotment of a share in the capital;

(e) The sharing in the control of the business by the representatives of labour.

The system arouses and sustains the interests of the workers in their work. By giving them a voice in the management of the factory, it raises their status as well. As they have become partners in the business, they try to make it a very profitable enterprise.

Type # 11. Accelerating Premium Systems:

There are the systems which provide for a guaranteed minimum wage for output below standard.

For low and average increases in output above the standard, small increment in earnings are allowed. Increasingly, large earnings are conceded for above average output, the increment being different for each 1% increase in output. Very significant increases in earnings are given for really high output.

In this system, the production is pushed up higher and higher by discouraging low output and rewarding at an increasingly effective rate of higher outputs.

Such schemes are generally adopted when much higher outputs than what are currently obtained are to be achieved.

Long-Term Wage Incentive Plans:

Under such plans, each member of the group receives a ‘bonus’ based on the output of the group as a whole. There are several reasons for adopting such a plan. Sometimes (as on assembly lines) several jobs are inter-related. Here one worker’s performance reflects not only his own effort but that of his co-workers too.

In such cases, group incentive plans are advantageous. Secondly, such plans also encourage co-operation among group members. There tends to be less bickering among group members as to who has “tight” production standards and who has “loose” ones. Thirdly, the groups can bring pressure to bear on their members (through badgering, ostracism, etc.) and help keep shrinkers in line.

This, in turn, can help eliminate some of the needs for close supervision. Fourthly, group production levels tend to be more stable than individual ones, and group incentive payments vary less than individual ones. Finally, group incentive plans also facilitate on-the-job training, since each member of the group has a vested interest in getting a new group member trained as well as quickly as possible.

The chief disadvantages of the group plans are- (i) each worker’s rewards are no longer based solely or directly on his own efforts. To the extent that the person does not see his effort leading to the desired reward, a group plan is probably not as effective as an individual plan, (ii) there is unevenness of performance of different members of the group and this may have resentment of active members against mere ‘passengers.’ (iii) ill-feeling may be generated among the groups themselves where the technology is such that one group’s earnings depends on the performance of another group.

Group incentive plans are usually applied to small work groups, for example, 5 or 6 people who must assemble a component together.

The incentives usually take three forms:

I. A Standard Output:

(a) A standard output, i.e., target production, may be laid down for a month or a longer period and bonuses are paid if this is achieved and 7 A standard output per man-hour is laid down for a department or for the plant as a whole, and the bonus is paid in proportion to which the actual output per man-hour exceeds the standard, the other conditions of work remaining the same.

II. The ‘Value Added’ by Manufacture at factory cost leading to cost reduction forms the basis for calculating the bonus. If the actual cost of production is lower than the ‘standard cost’ to the extent the workers are able to influence such reduction — by harder working, saving in materials, fuels, lubricants, etc., – a bonus whose money value is a percentage to the cost reduction is paid.

III. Bonus can also be calculated on the Increased Value of Sales where this result is obtained by increased production.

The Group Incentive Plans are usually:

(i) The Profit-sharing schemes and

(ii) The Scanlon Plan.

Types of Incentive Plans- With Formula, Advantages and Disadvantages

In an individual incentive plan, the rewards of incentives are based solely on individual performance, where an individual can increase the quantity and quality of his output by his own individual efforts and where his output can be measured. The rewards under such plan are almost immediate, that is, paid daily or weekly. Individual incentive plans are of two types. These are time based individual incentive and output based individual incentive plans.

The different time based individual incentive plans are discussed below:

1. Halsey Plan:

It is a plan originated by F.A Halsey to encourage efficiency amongst workers as well as to guarantee them wages according to time basis. The standard time required for a job is determined beforehand on the basis of time and motion studies.

Workers who perform the job in less than the standard time and thus save time are rewarded with a bonus but the worker who takes longer time than the standard time is not punished and is paid wages according to time wage system.

The total wage is calculated as:

T x R + 50 % (S-T) x R

Where T -Time taken

R- Rate of wage

S- Standard time

Illustration:

S = 10, R = Rs.5, T = 6

Wages = 6 x 5 + 50 % (10 – 6) x 5 = Rs.40

Here the worker will also earn something more by utilizing the time saved by him.

Advantages:

i. It is simple and easy to understand.

ii. There is guaranteed minimum wage.

iii. Under this method, management share a part of bonus on time saved.

Disadvantages:

i. Workers get only half of the benefit of their efficiency.

ii. If the workers rush through the job to save time, the quality may suffer.

iii. Sufficient incentive is not provided to fast workers.

2. Rowan Plan:

This is a modified form of Halsey Plan, developed by James Rowan of England. The Rowan Plan pays more than the Halsey Plan. This is possible if a worker completes the task in half the standard time of the task. If more than 50% time is saved then the bonus decreases.

The only difference between Halsey Plan and Rowan Plan relates to the calculation of bonus. Under this plan bonus is based on that proportion of the time saved which the time taken bears to the standard time.

It can be expressed as follows:

Total wage = T x R + T x R x (Time saved/Standard time)

Illustration:

S = 10, R = Rs.5, T = 6

Wages = 6 x 5 + 6 x 5 x (4/10) = Rs.42

Advantages:

i. It guarantees minimum wages to the workers,

ii. Both the employers and workers share the benefits of time saved.

iii. The efficient workers get bonus at diminishing rate if they save more than 50% of the standard time. This checks over-speeding.

Disadvantages:

i. Incentive provided for fast worker is not sufficient,

ii. Workers dislike the sharing of bonus by employers.

3. Bedeaux Plan:

This plan was developed by Charles E. Bedeaux in 1911. Here the minimum time wage is guaranteed to all workers. The workers who complete the job within or more than the standard time are paid at the normal time rate.

Under this plan, the standard hour would consist of 60 B’s, or a standard day of 8 hours i.e. 480 B’s. Workers who complete the job in less than the standard time are paid bonus generally 75% of the wage for the time saved and 25% to the foreman.

The wage rate is calculated as:

Wages = S x R + 75% of R (S-T)

Illustration:

S = 10 hrs; R = Rs.5/hrs; T = 8hrs.

Then Wage = 10 x 5 + 75% of 5 x (10-8) = Rs.57.50

Advantages:

i. Minimum wage is guaranteed to all the workers,

ii. The foreman is motivated to the productivity as 25% of time saved is paid to him.

Disadvantages:

i. Workers may resent sharing of bonus with foreman,

ii. It is difficult to understand the complete calculation involved in this method.

4. Emerson’s Efficiency Plan:

This plan was developed by Harrington Emerson. Here minimum wage is guaranteed. Workers are paid different bonus rates as per their efficiency level. Bonus is given at an increasing percentage beyond the prescribed level of efficiency. Efficiency is measured by comparing the actual time taken with the standard time.

The wage rate is calculated as:

W= (T x R) + (Percentage of bonus x T x R)

Illustration:

S = 10 hrs; R = Rs.5/hrs; T = 8 hrs.

Bonus = 10% up to 75% efficiency

20% for 75%-100%

30% beyond 100%

In this case, the efficiency level is 10/8 x 100 = 125% and bonus payable will be 30%.

Total wage = 8 x 5 + 30/100 (8×5) = Rs.51

Advantages:

i. Guaranteed time wage provides a sense of security to all the workers.

ii. It encourages healthy competition among workers.

Disadvantages:

i. There is little incentive after 100% efficiency level.

ii. The plan is not very flexible or selective.

The different output based individual incentive plans are discussed below:

a. Taylor’s Differential Piece Rate Plan:

Under this plan, a standard task is established by the techniques of time and motion study and two piece rates are set up for each job. A high piece rate is allowed to those who can make equal to or higher than the standard performance, and for others who cannot reach the standard, a lower piece rate is applied.

Illustration:

A standard output of 200 units is fixed in an 8 hours’ time. A rate of 45% is paid if the output is 200 or more and 35% if production is less than 200 units. Worker A has produced 250 units and worker B produced 190 units.

In this case, the wage to be paid to worker A will be (250 x .45) = Rs. 112.50 and that to B will be (190 x 35) = Rs. 66.50

b. Merrick Multiple Piece Rate Plan:

It is a modified plan over Taylor’s differential piece rate plan.

According to this plan, three piece rates are applied in the manner given below:

Rates:

1. Upto831/3% – Normal Rate

2. Above 831/3% to 100% – 110% of Normal Rate

3. Above 110% – 120% of Normal Rate

Illustration:

Actual output is 80 units, standard output is 100 units, and normal rate is 10 per unit. Compute the earning.

In this case, efficiency is = (80/100) x 100 = 80%

As the efficiency is less than 83%, only the base piece rate applies- 80 x 10 = Rs. 800

Illustration:

Actual output is 90 units, standard output is 100 units, and normal rate is 10 per unit. Compute the earning.

In this case, efficiency is = (90/100) x 100 = 90%

As the efficiency is 90% but less than 100%, 110 % of the base piece rate applies: (90 x 110/100) x 10 = Rs. 990

Illustration:

Actual output is 110 units, standard output is 100 units, and normal rate is 10 per unit. Compute the earning. In this case, efficiency is = 110/100) x 100 = 110%

As the efficiency exceeds 100%, 120 % of the base piece rate applies: (110 x 120/100) x 10 = Rs. 1320

c. Gantt Plan:

This plan was developed by Henry L. Gantt. The worker receives the bonus only if he attains the required standard of efficiency. No bonus is paid to a worker where efficiency is less than 100%. The foreman is also given a bonus if the worker under his supervision attains the required standard of efficiency.

Illustration:

Suppose the standard time fixed for the job is 8 hours and time rate is Rs. 10 per hour and the rate of bonus is 25%, then a worker who completes the job in 10 hours will be paid Rs. 10 x 8 = Rs.80. On the other hand, the worker who completes the job in 6 hours will be paid Rs. 100 (Rs.80 + 25% of Rs.80).

Advantages:

i. It guarantees minimum wage.

ii. Fast worker is paid bonus at higher rate proportional to their output,

iii. Part of bonus is paid to the foreman.

Disadvantages:

i. There might be conflict between the slow and the fast worker.